CONSERVATION CONNECTION

The average family uses about 300 gallons of water per day. With 116 million households in the United States, water consumption can quickly add up. Recognizing the importance of water conservation–and to comply with new legislation–manufacturers are focusing on products that help reduce water usage.

“It’s essential we protect this valuable resource to ensure this life-sustaining resource remains available in the future.” — Cassandra Wurster, Zurn Industries

The Call for Action

“Currently, all potable water is exclusively derived from fresh water, which is less than 1 percent of all earth’s water,” says Cassandra Wurster, product training manager, Zurn Industries. “With a constant increase in population and industry worldwide, it’s essential we protect this valuable resource to ensure this life-sustaining resource remains available in the future.”

Upgrades & Innovations

Meeting the Challenges

“Perhaps the biggest challenge is creating awareness about the significance of water conservation and the long-term ramifications of their individual water usage coupled with the world’s water use practices and overall plumbing technologies,” says Wurster.

“There is no doubt that our newest technology can help building managers save energy and water. However, getting there requires sufficient willingness, understanding, and realistic budgets to make it happen,” says Cohick. “Education, and cost-of-operation and lifecycle studies go a long way in showing the value of installing the latest and most efficient technology.”

“Our latest products were developed exclusively to conserve water and to help commercial and industrial facilities comply with or exceed new restrictions on water use.” – Dustin Cohick, EVAPCO, Inc.

The Call for Action

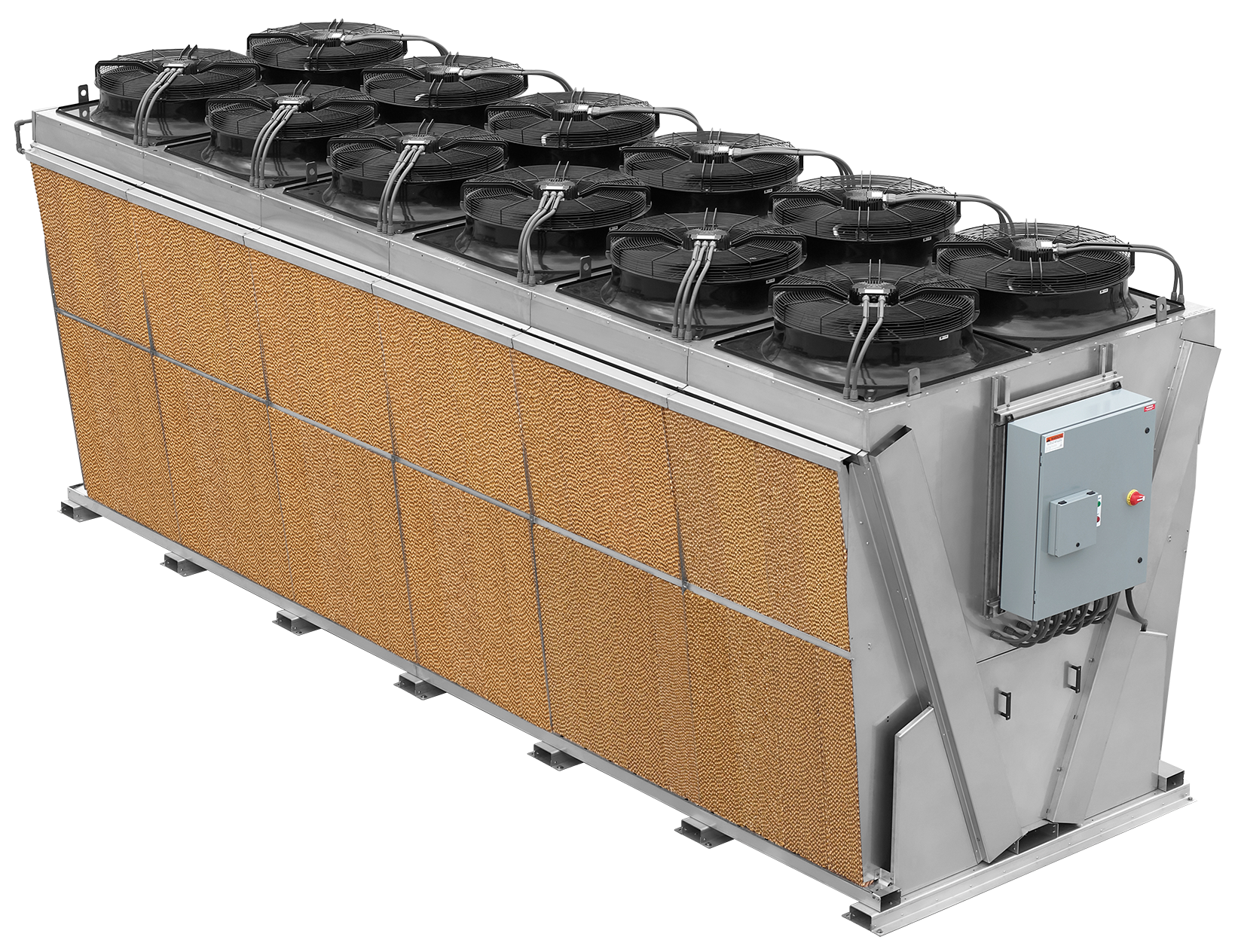

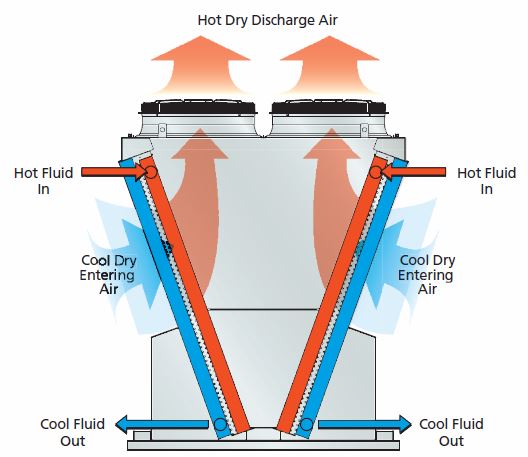

Dustin Cohick, assistant product manager, Dry & Adiabatic Coolers, HVAC and Industrial Process, EVAPCO, Inc., says their customers are becoming increasingly focused on the need for water conservation or compliance with new legislation. “National, state, and local governmental involvement and legislation advances the level of concern—especially among commercial and industrial users,” he adds. Ultimately, says Cohick, EVAPCO’s customers help shape their focus. “Throughout the country, there are droughts in some areas, high water rates in others, and a lack of quality water for evaporative equipment,” he says. “For these reasons and others, customers often choose to use equipment that uses less water.”

Affecting the Impact – the eco-Air Series

Upgrades & Innovations

“By focusing on new technology, we can make a big impact without adding complexity.” — Mark Chaffee, Taco Comfort Solutions

Affecting the Impact

With water needed to produce energy and energy needed to pump, treat, and transport water, the two resources are fundamentally linked. “The energy-water nexus is where our industry lives,” says Mark Chaffee, vice president, Governmental Affairs and Sustainability, Taco Comfort Solutions. “Choices made during system design can have a huge impact on the amount of energy and water that is consumed in a building.

“It’s our duty and responsibility as a manufacturer to have an impact on the environment and systems in which our products are used,” he adds. “Forty percent of the energy used in industrial applications goes towards pumping. By focusing on new technology, like ECM (electronically commutated motors) and self-sensing pump controls, we can make a big impact without adding complexity.”

New Rules from the Department of Energy

New Department of Energy rules go into effect in January 2020 that will eliminate 25 percent of the least efficient hydronic and domestic water pumps, says Chaffee.

“This rule, in combination with a new voluntary industry labeling program [Hydraulic Institute Energy Rating], should have a major impact on not only what is available in the market for higher-efficient products, but also how pumps are evaluated, specified, and purchased in the market,” he says. “The pump industry has taken a major step forward with these two initiatives and energy efficiency will be the winner.”

Upgrades & Innovations

Throughout its product lines, Taco has integrated ECM motors to help save up to 85 percent of the electrical energy used to power the company’s pumps, says Chaffee.

“Integrating the most advanced motors together with integrated variable speed drives and self-sensing logic in our SKS/SKV and SCI/SFI pumps permit them to self-optimize their performance, allowing almost any system or application to run more efficiently,” he says.

Meeting the Challenges

“How many times have we all waited for the shower to get hot, wasting all that water down the drain, but have still not done anything about it—and we’re in the business,” Chaffee says.

“Simple, cost-effective solutions exist, but one sometimes needs a motivational push,” he adds. “Or, simply ask a plumber or contractor about available options to solve problems. Today’s consumer, especially the millennials, are searching more and demanding more from their built environment and this includes using less resources in their daily lives.”